Welcome To Scantek, Inc.

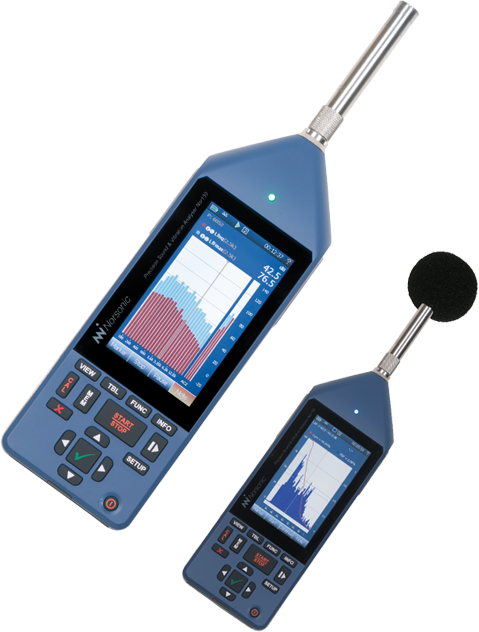

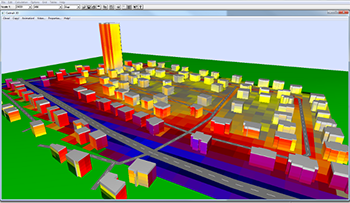

We are the leader in vibration and sound measuring equipment sales, service, rental, and calibration. Our mission is to sell, service, and rent the finest products while providing expert support on their use. The Scantek Calibration Laboratory is accredited for microphones, calibrators, sound level meters, dosimeters, sound and vibration FFT, and real-time analyzers, preamplifiers and signal conditioners, accelerometers, velocity sensors, vibration meters, and vibration exciters. At Scantek, we understand how important correct sound reading and output needs to be in professional settings. That is why we strive to provide each client with a caring sale experience as well as unparalleled support with their sound measuring equipment.